Acute arthritis of the spine and a garage barely wider than his 1974 Ford Capri GT, wouldn't stop Chris Wagstaff from completing his restoration dream.

Fortuna Audeces Juvat. It's not often that we open a feature with a Latin proverb, but the translation 'fortune favours the brave' seemed a fitting one, especially when talking about restorer Chris Wagstaff. When he was diagnosed with chronic arthritis of the spine, aged just 29, he decided to look for a project. ‘I figured that if I didn't start soon I may become to ill to complete my dream of restoring a classic, so I asked Jasmin [NOTE TO PRODUCTION – SPELT WITHOUT AN E] my partner if she thought it was a good idea,’ he says. She didn’t say no thanks to being asleep at the time, so Chris began his search for the perfect project.

In August 2013, Chris found this Capri 2000 GT. ‘It was on the internet for 99p ‘Buy It Now’ but the description said he wouldn’t let it go for less than ££££’s, so I emailed asking what he wanted.’ Chris didn’t receive a reply, so he offered £1000. He heard nothing back. ‘I thought “this is ridiculous” so emailed again offering £1650.' This combined with the assurance of instant payment and a next day collection, was enough for the reluctant vendor to phone him back.

‘He wasn’t interested in the car at all. He was a motorcycle dealer who’d taken it in as part-exchange from a friend who's owned the Capri since 1994,’ says Chris. The money from the sale was going to be used by the two friends to fund a round-Europe motorcycle trip. ‘He told me he’d had loads of ‘enthusiasts’ phoning him up and asking silly questions. I’m sure if he hadn’t been so curt with them he could’ve got more for it.’

Described as being part restored ‘welding done and ready for paint,’ the vendor had also made a big deal of its ‘new’ vinyl roof. On the face of it, it seemed the perfect recommissioning project for Chris to undertake. Money was paid, collection was arranged and the following day the Capri arrived from Leicestershire, where it had spent its entire life. The history that came it confirmed its 89,000 miles to be genuine and revealed Chris to be only the third keeper. It was the first time he’d seen the car, and initially it looked to be very good. Apart from the ripped vinyl roof…

‘It was seized solid so getting it into the garage was a laugh,’ says Chris. ‘Fortunately the delivery driver was a big bloke although we did block the road during rush hour for a bit. Sorry about that…’ Chris’s first job was to remove the brakes to allow the car to be rolled in and out of his small single garage, and to give his back a break. ‘I knew I’d struggle with space, so I’d already demolished the rear garage wall to allow me access to our small porch behind.’ Little did he know, but that four by six foot porch was about to become his workshop.

The brakes were in such poor condition that Chris replaced the entire system. ‘Reconditioned calipers cost only £10 more than the parts required to do it myself. That’s the beauty of Ford; if mechanical parts are available, they’re usually good value.’ Chris’s idea was to strip the car down, prep for paint, and paint it himself using cellulose. ‘I wanted to change it to bright orange, but after doing some research I discovered that the MkII 2-litre GT is now rare, with only six known survivors.’ Ford only produced the GT for 14 months, and they were the last Capri’s to be painted Daytona yellow. ‘After the MkII facelift they changed to Signal yellow, so I decided to stick with Daytona.’

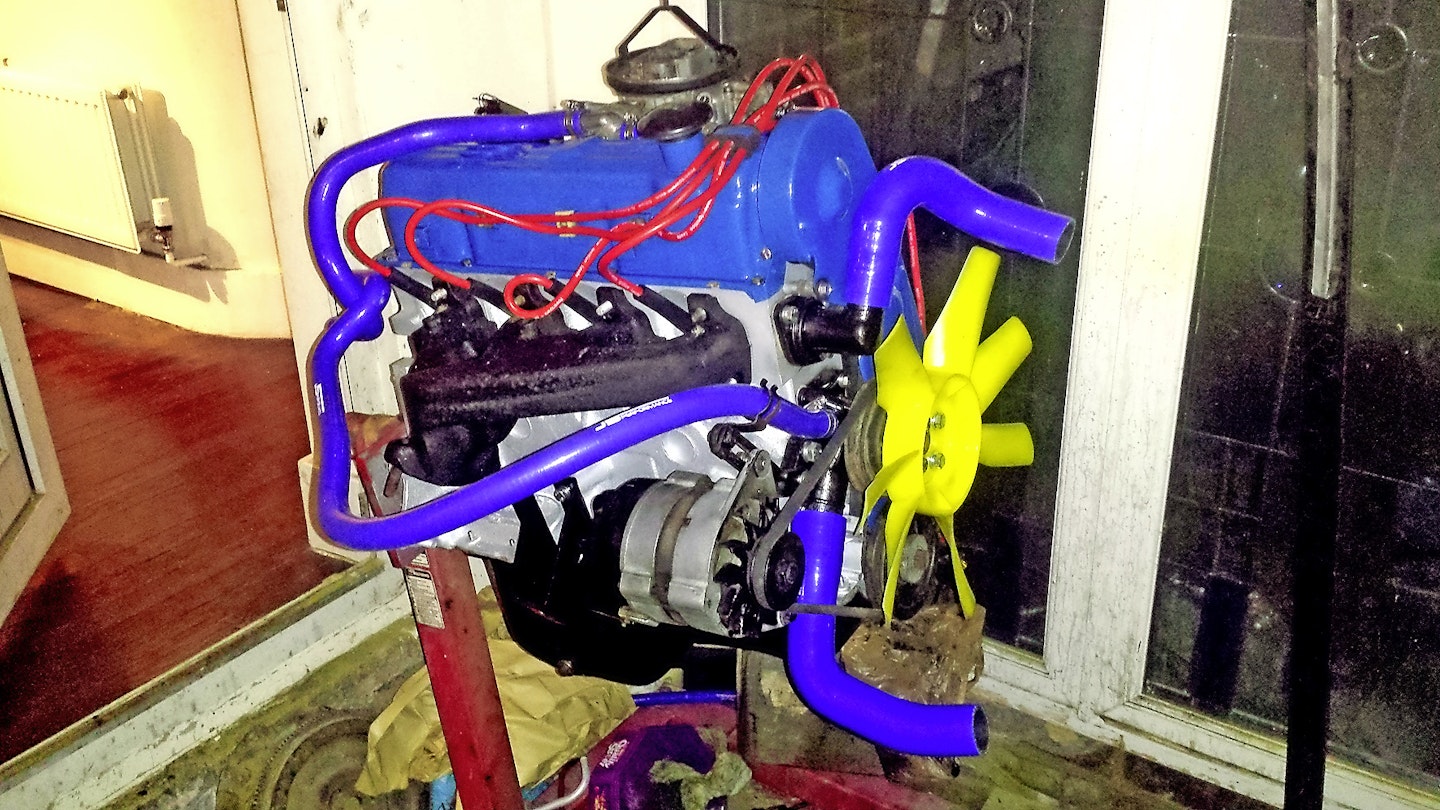

Chris managed to get the engine running, albeit on three cylinders, but both compression and oil pressure were good which was encouraging. ‘I decided to take the engine out to strip and inspect it anyway. I didn’t have an engine lift, so I bought an old one for £100. The engine work was all conducted in the porch.’ Chris also bought a secondhand compressor for £120. ‘It was the biggest sized compressor you can run on single phase electricity and I couldn’t fit it in my garage.’ Not one to be beaten, Chris put it in his shed, running an air-line through the garden and into the house, via the letterbox.

‘I don’t know what the postman made of it all, but it was there for the duration.’ Unfortunately, Chris’s back problems continued to get worse. ‘I carried the back axle into the garden to strip, inspect and paint it, but when it came to refit I had to get help to move it, for example.’ Chris had always suffered with back issues which he put down to working outside in the wet and cold, fitting exhausts to army trucks as a teenager. He only sought medical advice after downloading a ‘health check’ app to his mobile phone.

‘An MRI scan revealed that my lower back was in a similar condition to that of an arthritic 65 year old. My disks are compressing my sciatic nerve. I’m in constant pain and nothing can be done, apart from pain killers when it gets really bad.’ Chris had a string of restorations behind him, but he had never quite finished any of them. 'I was determined to see this one through, as it may be my last chance.' He’d already discovered that a little welding was required in the rear wheelarches but the rest of the car looked sound, just as described. Nevertheless, Chris stripped the body down to the last nut, just in case and it's a good thing he did.

'While removing the interior I noticed a chink of light coming into the drivers footwell. Then I noticed the same on the passenger side. I thought, “I’m no expert, but If there’s a hole in the floor, your feet would get wet," surely?’ Chris began to delve deeper, and what he found was horrible. ‘The ends of the sills must have rusted so someone had simply chopped them off. Then I discovered the B pillars weren’t attached to the sills and were just floating.’ To disguise this dangerous bodge, new pattern panels had been welded over the top.

‘I bit the bullet and chopped the wings off,’ says Chris. But worse was to come. The front Valance, another new pattern panel, was held on not by weld, but with filler. 'That had to come off too.’ The panel under the headlights was made of half an inch of filler so that came off too. Chris’s recommissioning project was becoming more involved by the minute. ‘They’d simply put the new wings on over rust. It was terrible.’ Worse still, the inner wings were largely made of filler. ‘Tugging on the welded repairs that had been made was enough to dislodge them, such was the quality of the work,' says Chris. Before he knew it, he had a full restoration on his hands.

Both inner wings were indeed rotten, and only one side of the four-sided front crossmember and slam panel was any good. Chris rebuilt them all. Curiously the strut tops and bulkhead – usual Capri weak spots – were both perfect and thankfully, when Chris stripped the engine in his porch, the diagnosis was good. With only 89,000 miles under its belt it needed only the bare minimum of work. The head, bores and pistons were all checked and found to be in rude health. When Chris replaced the cam belt he discovered the old one was a couple of teeth out, probably leading to poor running – was this why the car had been taken off the road?

A new silicone hose set was installed, as was a brand new distributor complete with electronic ignition. ‘The new dizzy only cost £10 more than buying new points, cap, leads, rotor and condenser. It was a no-brainer.’ New belts, fuel and brake lines were added and the radiator recored with a new deeper matrix. Braided fuel lines finished the job. As well as conducting the mechanical work, Chris was also gradually piecing the body back together again.

‘I had to make my own repair sections. MkII Capri’s aren’t well served with panels like the other models so I had to go it alone,’ Chris says. By the end of 2013 the body was finished and in primer. ‘I sprayed the primer in September and the weather was still quite nice.’ However, by the time it came to apply the top coats things had got considerably colder. ‘My top coats didn’t go on as well, it was too cold for the paint to set properly so it sagged and ran.

It was a killer, especially in my small garage. I had to sand it all back and start again, which didn’t do my back much good. 'In total, Chris used just five litres of primer but 15 litres of Daytona yellow top coat. ‘I did the best job I could, especially with my back and in a garage barely wider than the car.’ Chris was about to refurbish his wheels when he noticed a finished set on eBay. ‘They came fitted with new tyres and were much cheaper that refurbishing my own. They were a bargain.’

A mere nine months after work on the car had begun, Chris drove a shiny Capri GT out of his garage to the MoT station. It passed its first MoT in twenty years with no advisories. Chris's restoration truly is an inspiration, a victory in the face of adversity. ‘I’m pleased with the result, especially as I had to complete it quickly while I still could.' Now that's obviously a bit of an understatement from Chris, so we've decided to end on something a touch more grand, fugenit invida aetas: carpe diem. Jealous time will have been flying: seize the day.