Weekend workshop: save £200 in four hours

We explain how to test and rebuild your alternator for as little as £20

THE PC JOB CARD

ALTERNATOR REBUILD

Using a Lucas 15 ACR as a guinea pig, we'll reveal all you need to know to diagnose and rectify faults in a typical alternator. There are many designs, but the basics are the same.

You’ll need

Multimeter

0-75A ammeter

Relay and push switch

Charged car battery

Wire

Crocodile clips

Two- or three-legged puller

Soldering iron

Flux and solder

Will take (HR) 4

Will cost (£) 20

Money saved (£) 200

GET GOING

1 The basic principle

When a conductor (the wire) is moved through a magnetic field, a current flows in one direction. Reversing the wire’s direction reverses the flow. The output is increased by having a stronger magnet, using several wires or moving them faster.

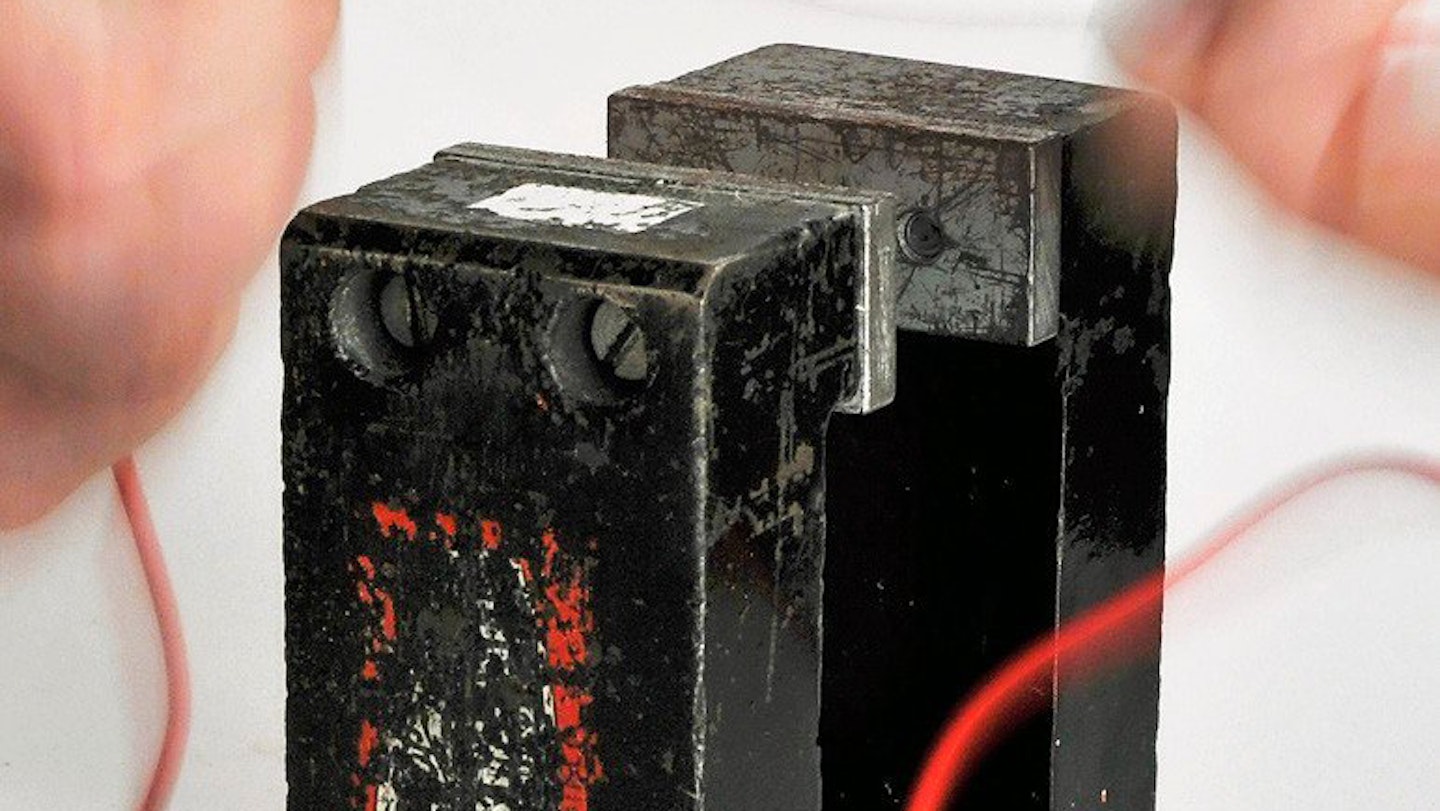

2 The rotor

An alternator works by rotating a magnet – the rotor. Its magnetic field moves through static conductors. It comprises of a piece of wire wound around an iron core. The ends are connected to circular contacts, called slip-rings.

Want to read the rest of this technical guide? Choose a Print + Digital subscription. You'll get instant digital access PLUS FREE UK delivery so you'll never miss an issue again.